Maraging 300 - UNS K93120 / DIN 1.6356 / AMS 6521

Maraging 300 is a high-performance alloy known for its exceptional strength, excellent resistance to oxidation, and stability at high temperatures. It is particularly suited for applications in the aerospace, power generation, and chemical industries, where both durability and resistance to extreme conditions are essential.

This alloy offers superior performance in high-stress and high-temperature environments, making it ideal for critical industrial applications.

Maraging 300 Plates & Sheets

Maraging 300 plates and sheets provide the strength and durability required in high-temperature environments such as turbine blades, reactor components, and aerospace applications.

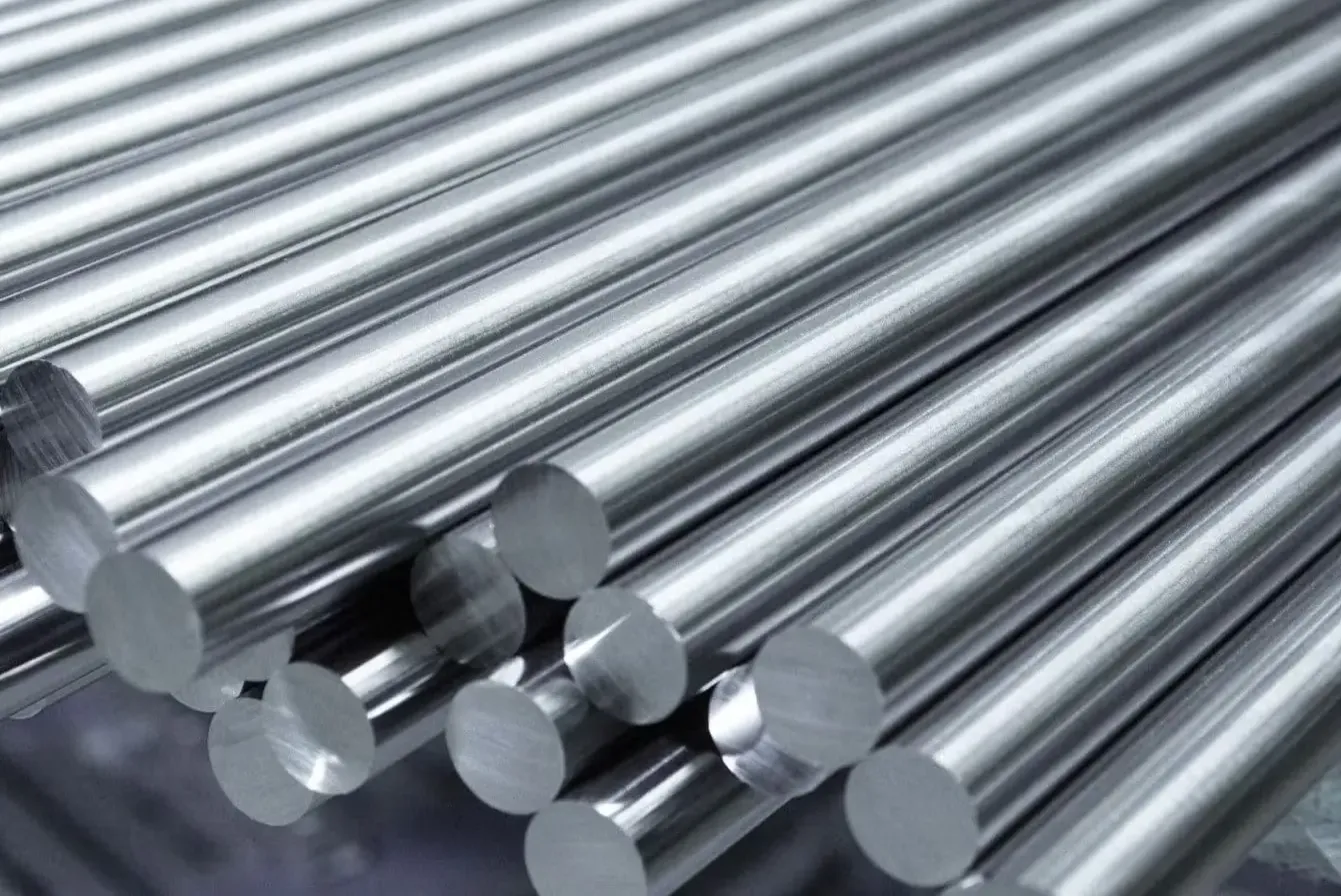

Maraging 300 Round Bars

Maraging 300 round bars are used to manufacture high-performance shafts, gears, and other components that must withstand mechanical stress and high temperatures in demanding environments.

Maraging 300 Flanges

Maraging 300 flanges are designed for use in high-pressure, high-temperature systems, ensuring reliable connections and excellent resistance to corrosion and oxidation.

Maraging 300 Fittings

Maraging 300 fittings are resistant to thermal stress and corrosion, making them ideal for applications in industries such as power generation, chemical processing, and aerospace.

Maraging 300 Tubes & Pipes

Maraging 300 tubes and pipes are used in heat exchangers, reactors, and piping systems, offering high strength and resistance to corrosion and high temperatures.

Maraging 300 Fasteners

Maraging 300 fasteners are designed to hold up under extreme pressure and temperature conditions, providing reliable fastening solutions for industrial machinery and critical infrastructure.

Maraging 300 Nut Bolts

Maraging 300 nut bolts offer exceptional strength and resistance to corrosion in harsh environments, making them suitable for high-performance machinery, power plants, and aerospace applications.

Applications of Maraging 300

- Aerospace: Used in engine components, turbine blades, and other high-stress parts exposed to high temperatures.

- Power Generation: Ideal for use in steam turbines, reactors, and other equipment that operate under extreme conditions.

- Chemical Processing: Commonly used in reactors, pumps, and valves in corrosive and high-temperature environments.

- Marine Engineering: Suitable for use in high-pressure systems such as exhaust systems and turbine components in marine environments.

Chemical Composition of Maraging 300

- Nickel (Ni): 50.0% - 60.0%

- Chromium (Cr): 15.0% - 20.0%

- Iron (Fe): Balance

- Aluminum (Al): 1.5% - 2.5%

- Titanium (Ti): 0.6% - 1.2%

- Cobalt (Co): 0.5% max

- Carbon (C): 0.05% max

- Manganese (Mn): 1.0% max

- Silicon (Si): 0.6% max

- Sulfur (S): 0.02% max

- Phosphorus (P): 0.04% max