Alloy 718 - UNS N07718 / DIN 2.4668 / ASTM B637

Alloy 718, also known as Inconel 718, is a high-strength, corrosion-resistant nickel-chromium alloy designed for extreme environments. It offers outstanding resistance to both high and low-temperature environments, along with excellent weldability and formability. This alloy is commonly used in the aerospace, chemical processing, and power generation industries due to its high strength and ability to withstand intense conditions.

Alloy 718 provides exceptional performance in high-stress, high-temperature, and corrosive environments, making it ideal for critical applications where both strength and resistance to corrosion are crucial.

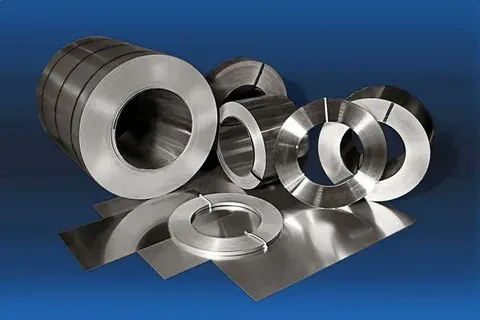

Alloy 718 Plates & Sheets

Alloy 718 plates and sheets are designed for use in aerospace components, chemical reactors, and industrial applications where resistance to high temperatures and stress is required.

Alloy 718 Round Bars

Alloy 718 round bars are ideal for manufacturing high-strength fasteners, shafts, and other components for industries like aerospace, power generation, and oil & gas.

Alloy 718 Flanges

Alloy 718 flanges are used to ensure reliable, high-strength connections in critical systems, especially in the aerospace, energy, and chemical processing industries.

Alloy 718 Fittings

Alloy 718 fittings are highly durable and resistant to corrosion, making them suitable for high-stress and high-temperature applications, particularly in gas turbines and heat exchangers.

Alloy 718 Tubes & Pipes

Alloy 718 tubes and pipes are used in a variety of high-performance applications, including heat exchangers, jet engines, and gas turbines, where strength and resistance to high temperatures are essential.

Alloy 718 Fasteners

Alloy 718 fasteners offer exceptional strength, corrosion resistance, and fatigue resistance, making them ideal for use in aerospace, energy, and high-stress environments.

Alloy 718 Nut Bolts

Alloy 718 nut bolts are used in heavy-duty applications where superior strength and resistance to high temperatures and corrosion are required, such as in gas turbines and reactors.

Applications of Alloy 718

- Aerospace Industry: Used in turbine blades, structural components, and rocket engines due to its high strength at elevated temperatures.

- Power Generation: Ideal for gas turbines, steam turbines, and reactors where strength and heat resistance are essential.

- Chemical Processing: Used in reactors, heat exchangers, and pressure vessels handling high temperatures and corrosive environments.

- Oil and Gas Industry: Commonly used in subsea and downhole applications, as well as in pumps and valves exposed to high stress and temperature.

Chemical Composition of Alloy 718

- Nickel (Ni): 50.0% min

- Chromium (Cr): 17.0% - 21.0%

- Iron (Fe): 18.0% - 21.0%

- Molybdenum (Mo): 2.8% - 3.3%

- Niobium (Nb): 4.75% - 5.5%

- Titanium (Ti): 0.65% - 1.15%

- Aluminum (Al): 0.2% - 0.8%

- Cobalt (Co): 1.0% max

- Carbon (C): 0.08% max

- Manganese (Mn): 0.35% max

- Silicon (Si): 0.35% max

- Sulfur (S): 0.015% max