Alloy 825 - UNS N08825 / DIN 2.4858 / ASTM B424, B425

Alloy 825, also known as Incoloy 825, is a nickel-iron-chromium alloy that offers excellent resistance to a wide range of corrosive environments. It is especially resistant to sulfuric acid, phosphoric acid, and seawater. Alloy 825 is commonly used in the chemical, petrochemical, and marine industries for its ability to withstand highly corrosive environments at both high and low temperatures.

Thanks to its outstanding corrosion resistance, Alloy 825 is frequently utilized in chemical processing equipment, pollution control equipment, and marine environments where resistance to pitting and crevice corrosion is essential.

Alloy 825 Plates & Sheets

Alloy 825 plates and sheets are highly resistant to corrosion in sulfuric acid, phosphoric acid, and seawater, making them ideal for applications in chemical processing plants, oil refineries, and offshore structures.

Alloy 825 Round Bars

Alloy 825 round bars are used in a variety of industrial applications, including fasteners, shafts, and valves, where resistance to both corrosion and high temperatures is critical.

Alloy 825 Flanges

Alloy 825 flanges provide reliable and durable connections in high-temperature and corrosive environments. They are commonly used in chemical processing and marine applications.

Alloy 825 Fittings

Alloy 825 fittings offer superior performance in piping systems that require resistance to high-temperature corrosion, including those found in the petrochemical and marine industries.

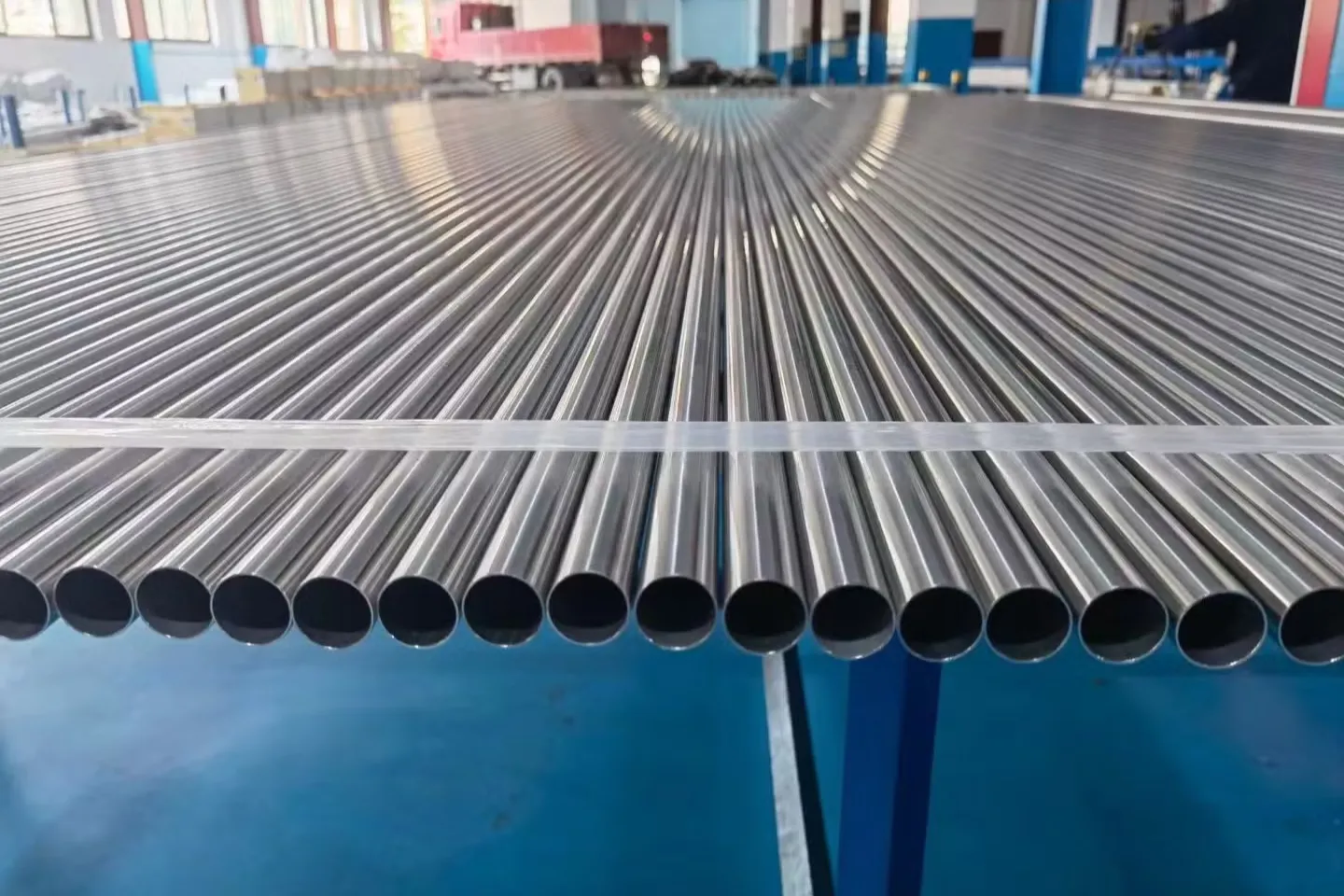

Alloy 825 Tubes & Pipes

Alloy 825 tubes and pipes are commonly used in heat exchangers, reactors, and pollution control systems where resistance to both stress-corrosion cracking and sulfuric acid is essential.

Alloy 825 Fasteners

Alloy 825 fasteners are designed for use in corrosive and high-temperature applications, including the aerospace, chemical processing, and offshore industries.

Alloy 825 Nut Bolts

Alloy 825 nut bolts are widely used in industrial machinery, pressure vessels, and structural components exposed to aggressive chemical and marine environments.

Applications of Alloy 825

- Chemical Processing: Used in reactors, heat exchangers, and tanks exposed to acids and alkalis.

- Petrochemical Industry: Ideal for applications in refineries and offshore platforms where high-temperature resistance is needed.

- Marine Environments: Suitable for use in offshore oil rigs and seawater systems due to its corrosion resistance.

- Pulp and Paper Industry: Used in equipment exposed to corrosive chemicals such as sulfuric and phosphoric acid.

Chemical Composition of Alloy 825

- Nickel (Ni): 38.0% - 46.0%

- Chromium (Cr): 19.5% - 23.5%

- Iron (Fe): Balance

- Nickel (Ni): 38% - 46%

- Carbon (C): 0.05% max

- Manganese (Mn): 1.0% max

- Silicon (Si): 0.5% max

- Sulfur (S): 0.02% max

- Phosphorus (P): 0.04% max

- Aluminum (Al): 0.2% max

- Columbium (Nb): 1.0% - 1.5%