Stainless Steel & Alloy Steel 13-8MO - UNS S13800, DIN 1.4548

13-8MO is a precipitation hardening stainless steel alloy known for its excellent strength and toughness. It is commonly used in aerospace and high-stress applications requiring excellent mechanical properties.

This alloy provides good resistance to corrosion and is ideal for use in applications like fasteners, shafts, and other structural components in aerospace and military sectors.

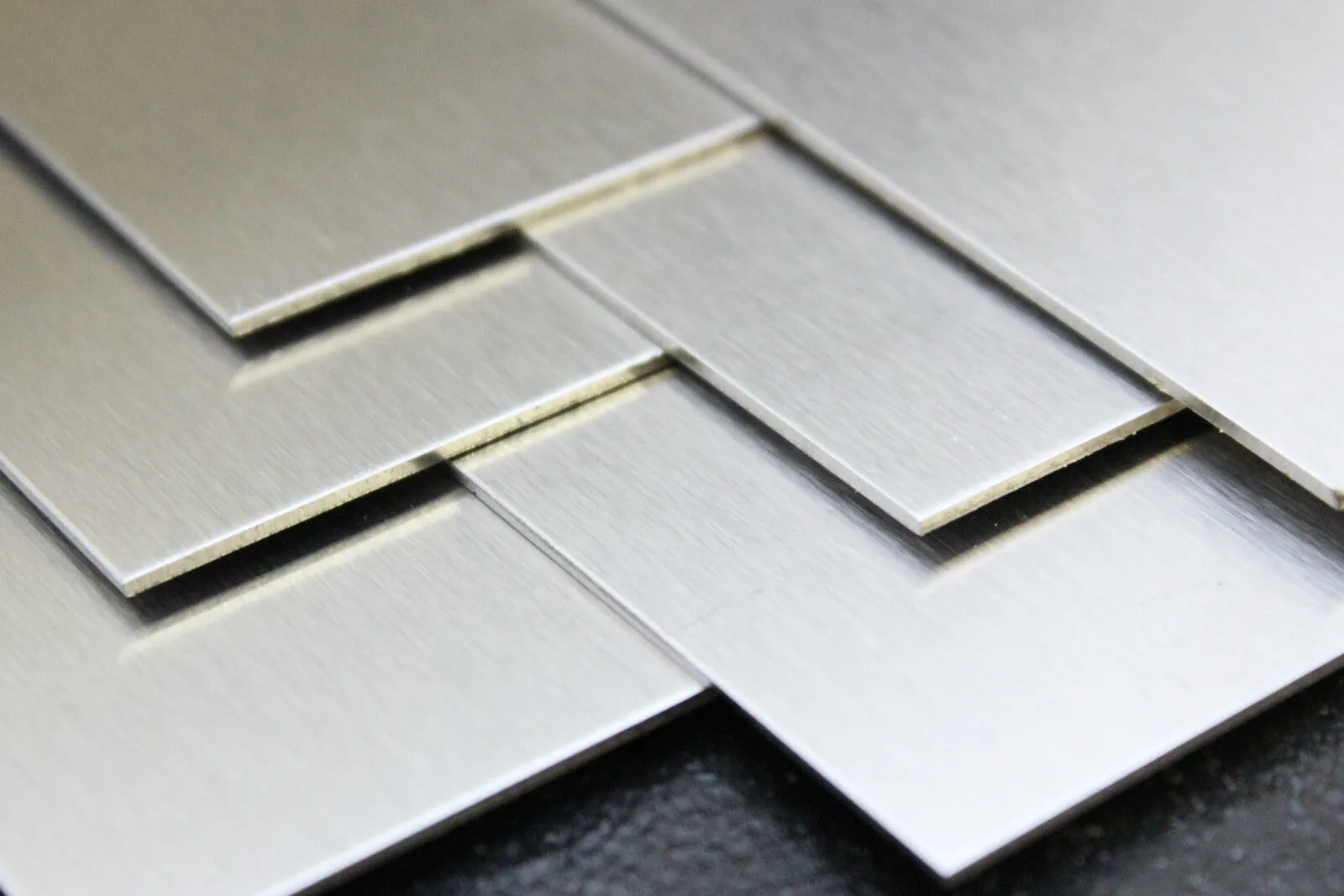

13-8MO Plates & Sheets

Plates and sheets made from 13-8MO are used in aerospace and high-performance applications where strength and corrosion resistance are crucial.

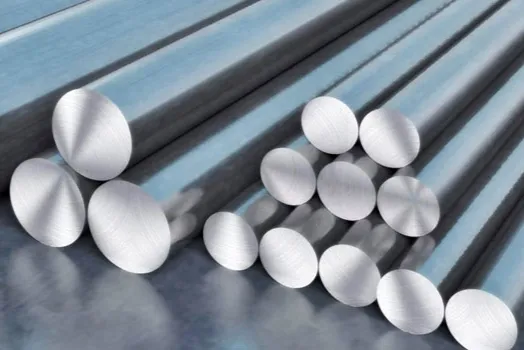

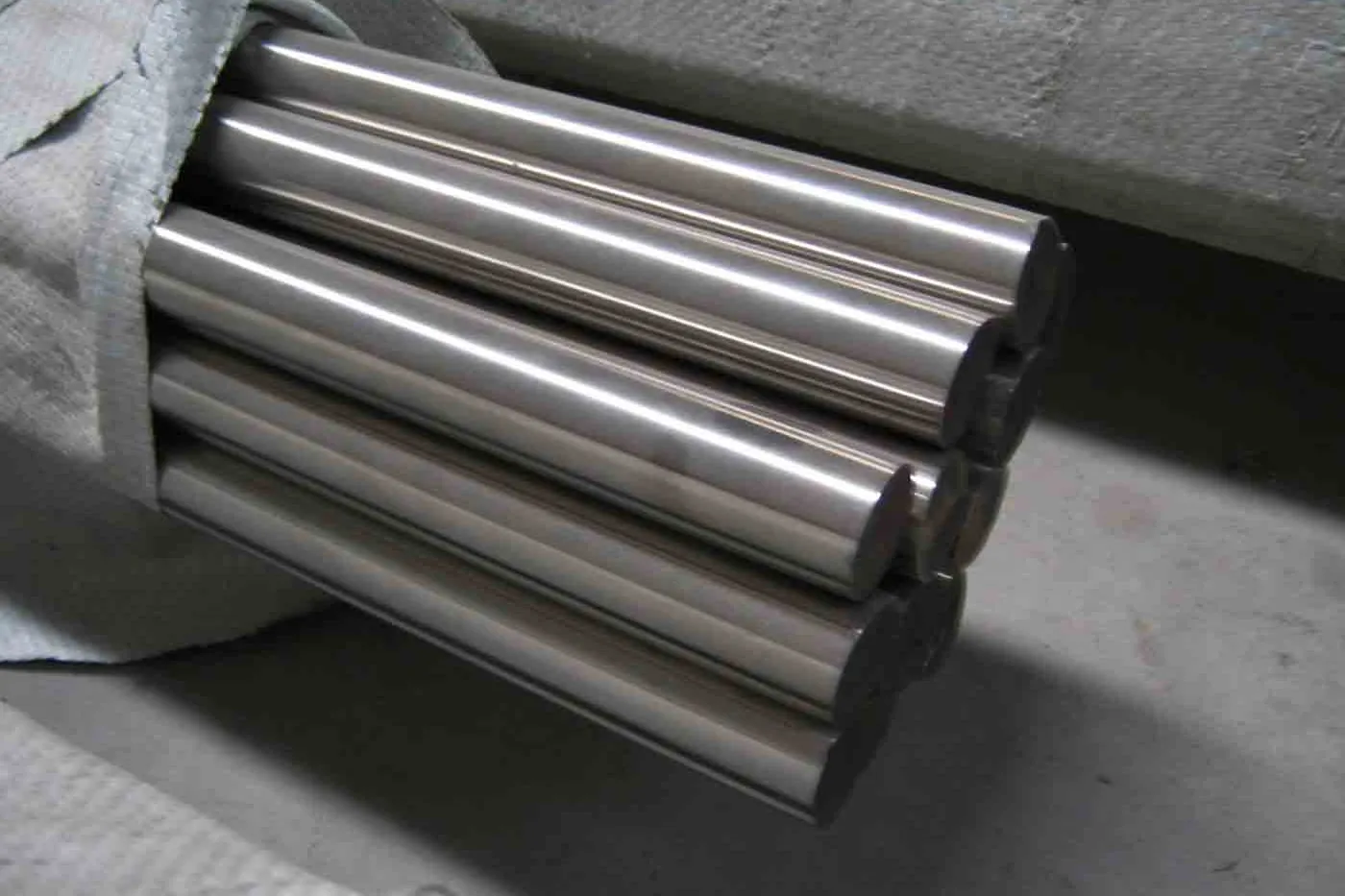

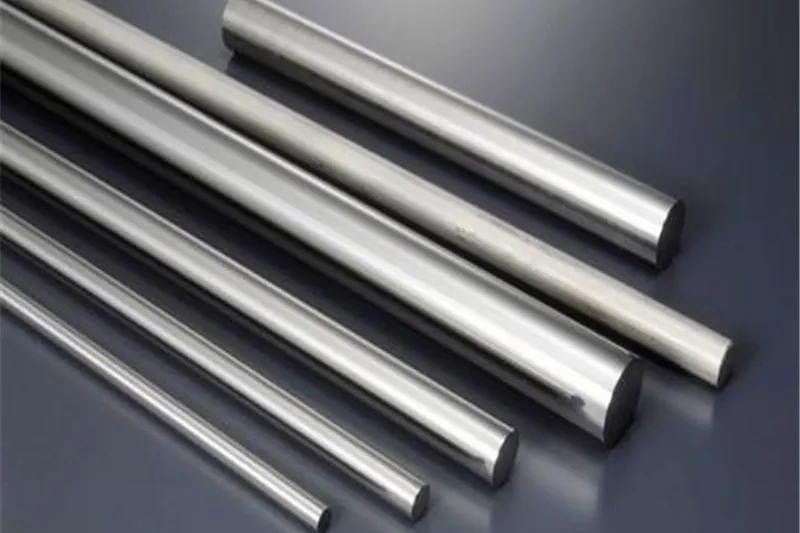

13-8MO Round Bars

13-8MO round bars are used in manufacturing aerospace fasteners, shafts, and structural components.

13-8MO Flanges

Flanges made from 13-8MO are ideal for high-pressure and high-stress applications in the aerospace industry.

13-8MO Fittings

Fittings made from 13-8MO offer excellent strength and corrosion resistance in demanding aerospace applications.

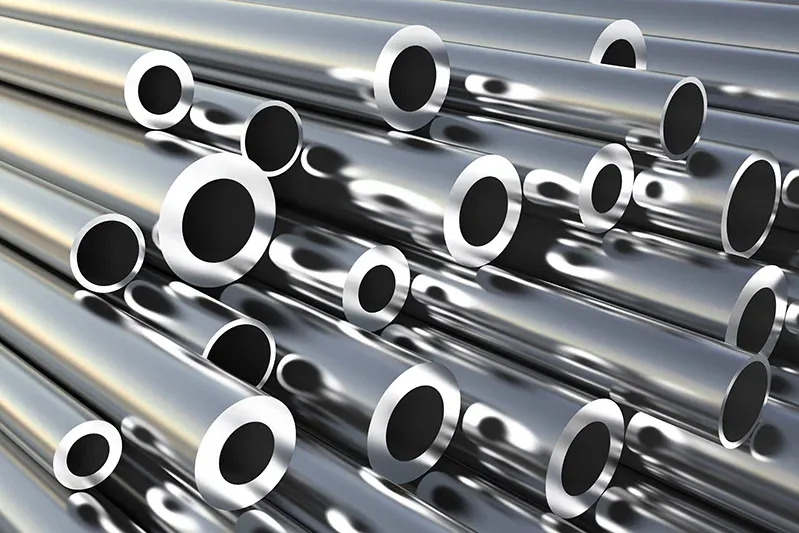

13-8MO Tubes & Pipes

13-8MO tubes and pipes are used in aerospace, military, and high-performance applications requiring high strength and resistance to stress.

13-8MO Fasteners

Fasteners made from 13-8MO are commonly used in high-stress aerospace and defense applications.

13-8MO Nut Bolts

13-8MO nut bolts are designed for use in high-performance environments requiring high strength and durability.

Applications of 13-8MO

- Aerospace: Used in turbine blades, aircraft components, and fasteners.

- Military: Used in high-performance military equipment and structures.

- High-performance Equipment: Ideal for high-stress mechanical components and fasteners.

Chemical Composition of 13-8MO

- Chromium (Cr): 12.0–14.0%

- Nickel (Ni): 7.5–9.5%

- Carbon (C): 0.03% max

- Manganese (Mn): 0.50–1.00%

- Silicon (Si): 1.0% max

- Phosphorus (P): 0.04% max

- Sulfur (S): 0.03% max

- Iron (Fe): Balance