Stainless Steel & Alloy Steel SS410 - UNS S41000, DIN 1.4006, AISI 410

Stainless Steel SS410 is a martensitic stainless steel that provides excellent corrosion resistance, good strength, and toughness. It is commonly used in applications requiring moderate corrosion resistance and high strength, such as valves, pumps, and kitchen equipment.

This alloy is easy to machine and weld, making it suitable for a wide range of applications in aerospace, automotive, and industrial sectors.

Stainless Steel SS410 Plates & Sheets

Plates and sheets made from SS410 are used in structural and industrial applications, offering resistance to corrosion and wear in moderately corrosive environments.

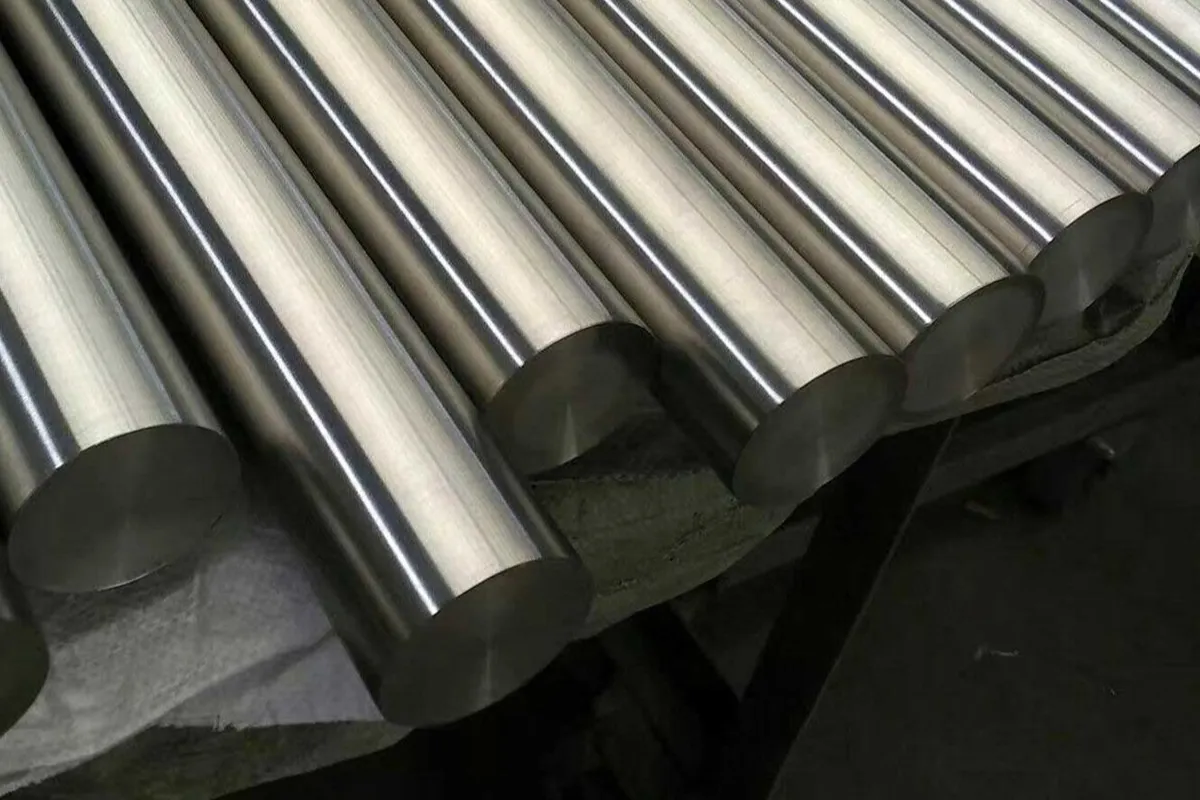

Stainless Steel SS410 Round Bars

SS410 round bars are widely used in the production of fasteners, shafts, and other components in the automotive and aerospace industries.

Stainless Steel SS410 Flanges

Flanges made from SS410 are resistant to corrosion and high temperatures, making them ideal for use in high-pressure systems, power plants, and chemical industries.

Stainless Steel SS410 Fittings

Fittings made from SS410 are widely used in piping systems and high-pressure equipment, providing excellent strength and corrosion resistance in demanding environments.

Stainless Steel SS410 Tubes & Pipes

SS410 tubes and pipes are widely used in industrial applications for their high strength and resistance to oxidation and wear.

Stainless Steel SS410 Fasteners

Fasteners made from SS410 are ideal for use in applications requiring strength, hardness, and moderate corrosion resistance.

Stainless Steel SS410 Nut Bolts

SS410 nut bolts are used in industries where high strength and resistance to wear and tear are needed.

Applications of Stainless Steel SS410

- Aerospace: Used in structural components and fasteners.

- Automotive: Suitable for exhaust systems, valve springs, and fasteners.

- Industrial Equipment: Used in valves, pumps, and other heavy-duty equipment.

Chemical Composition of Stainless Steel SS410

- Chromium (Cr): 11.5–13.5%

- Carbon (C): 0.15% max

- Manganese (Mn): 1.0% max

- Silicon (Si): 1.0% max

- Phosphorus (P): 0.04% max

- Sulfur (S): 0.03% max

- Iron (Fe): Balance