Aluminium 2219 - UNS A92219 / AMS 4031/4112/4162 / DIN 3.1355 / EN AW-2219 / BS L163

Aluminium 2219 is a high-strength, heat-treatable alloy primarily composed of aluminum and copper. Known for its excellent strength, toughness, and resistance to high-temperature environments, it is commonly used in demanding applications like aerospace, military, and industrial systems.

This alloy is highly valued for its superior mechanical properties, which include excellent weldability, high strength-to-weight ratio, and ability to perform well in cryogenic temperatures. Aluminium 2219 is often chosen for structural components, engine parts, and other critical applications requiring high strength and durability.

The addition of copper as the primary alloying element enhances the overall strength, while maintaining good machinability and resistance to corrosion in certain conditions. Aluminium 2219 is known for its high fatigue and impact resistance, making it a preferred material for aerospace structures and other high-performance components.

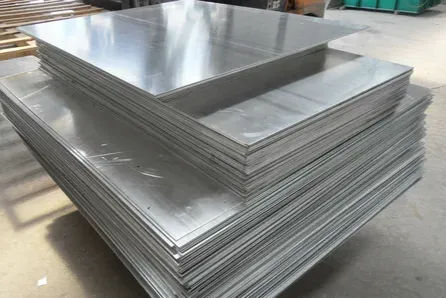

Aluminium 2219 Plates & Sheets

Aluminium 2219 plates and sheets are designed for use in applications where high strength, toughness, and resistance to extreme conditions are critical. They are used in aerospace components, high-performance machinery, and industrial systems requiring superior strength and reliability under high stress.

Aluminium 2219 Round Bars

Aluminium 2219 round bars are known for their excellent strength and machinability. These round bars are ideal for manufacturing high-stress components, including shafts, fasteners, and structural elements used in aerospace, automotive, and industrial applications.

Aluminium 2219 Flanges

Aluminium 2219 flanges provide a lightweight yet strong solution for connecting pipes and structural systems. With excellent strength and durability, these flanges are commonly used in aerospace, military, and industrial applications, where performance under high mechanical loads is crucial.

Aluminium 2219 Fittings

Aluminium 2219 fittings are designed for creating durable, high-strength connections in piping and structural systems. Known for their excellent weldability and resistance to fatigue, they are ideal for use in industries like aerospace, automotive, and defense.

Aluminium 2219 Tubes & Pipes

Aluminium 2219 tubes and pipes are used for fluid transport, structural applications, and systems where high strength and toughness are required. These tubes and pipes offer excellent resistance to mechanical loads and extreme temperatures, making them suitable for aerospace and military applications.

Aluminium 2219 Fasteners

Aluminium 2219 fasteners, including bolts, nuts, and screws, are designed for high-strength applications in aerospace, automotive, and industrial systems. Known for their durability and resistance to fatigue, these fasteners ensure strong, reliable connections in demanding environments.

Aluminium 2219 Nut Bolts

Aluminium 2219 nut bolts provide exceptional strength and resistance to high temperatures, making them ideal for use in aerospace, military, and heavy-duty industrial applications. Their high machinability and reliability make them a preferred choice for critical engineering projects.

Applications of Aluminium 2219

- Aerospace Industry: Used for high-strength structural components in aircraft, spacecraft, and satellites.

- Military Applications: Ideal for military vehicle frames, armor plating, and structural components for defense systems.

- High-Temperature Environments: Used in engine parts, heat exchangers, and other components exposed to extreme temperatures.

- Industrial Applications: Commonly used in pressure vessels, machinery parts, and heavy-duty structural systems.

- Heavy-Duty Fasteners: Frequently used in fasteners and joints in high-load environments.

Chemical Composition of Aluminium 2219

- Aluminum (Al): Bal

- Silicon (Si): 0.20% max

- Iron (Fe): 0.30% max

- Copper (Cu): 5.80 - 6.80%

- Manganese (Mn): 0.20 - 0.40%

- Magnesium (Mg): 0.02% max

- Zinc (Zn): 0.10% max

- Titanium (Ti): 0.02 - 0.10%

- Other Each: 0.050% max

- Other Total: 0.15% max

- Vanadium (V): 0.05 - 0.15%

- Zinc (Zn): 0.10 - 0.25%